Preparation for the reuse of certain timber and steel construction products

A guideline with recommendations for the reuse of timber and steel construction products was developed in collaboration with the Technical University of Munich and KIT Steel and Lightweight Structures. It shows ways and means of reclassifying components realised during dismantling so that they can be reused as load-bearing components in line with the circular economy. The main focus is on softwood lumber, glulam, OSB panels, I and H profiles made of structural steel as well as trapezoidal sheet metal and sandwich elements. Inspections of deconstruction objects and observations of deconstruction processes and structural conditions were key elements of the field research to ensure that the results for the guideline are in line with the "reality of deconstruction" and are adapted to the expected structural conditions.

Contact: Matthias Frese

Practical guide: Guide to the reuse of load-bearing components (PDF in German)

Research report: Preparation for the reuse of certain timber and steel construction products (in German)

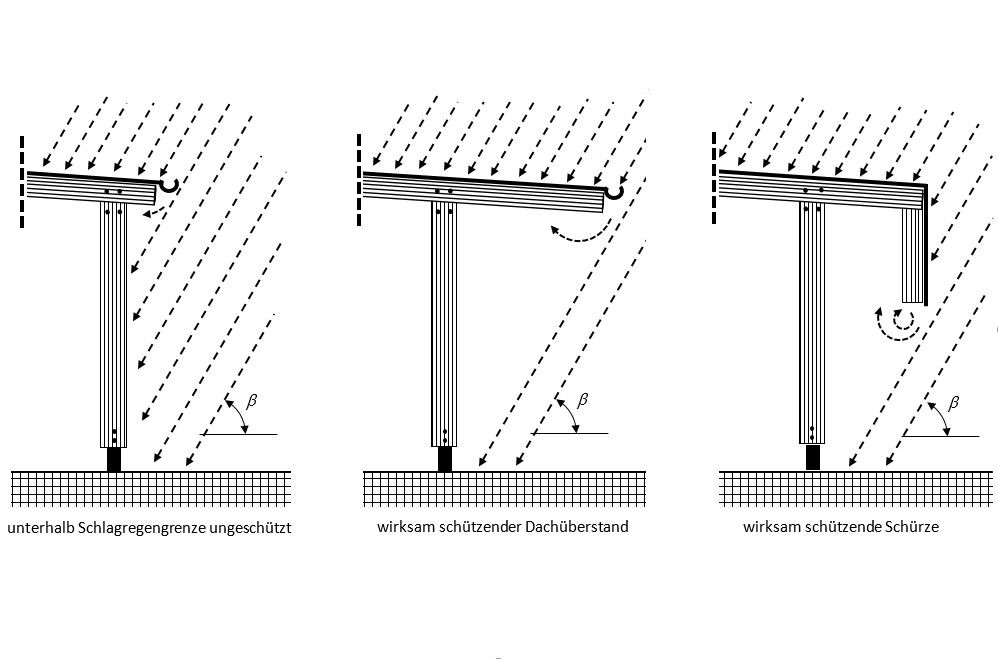

Construction principles, guiding details and recommendations for preventive structural timber protection

Positive and negative experiences with the durability of installed timber have shown that successful preventative structural measures are a guarantee for the long-term durability of installed timber. Such measures ensure that the wood is either always dry or almost always dry due to the potential for re-drying. On behalf of the Ministry of Regional Development and Housing BW, construction principles, guiding details and recommendations for preventive structural timber protection were developed, which are to be incorporated into DIN 68800-2 Timber protection - Preventive structural measures in building construction. Their observance during design, planning, execution and maintenance should contribute to the long-term durability of timber structures.

Contact: Matthias Frese

Final report: Karlsruhe Reports on Timber Engineering, Volume 41

Supported by:

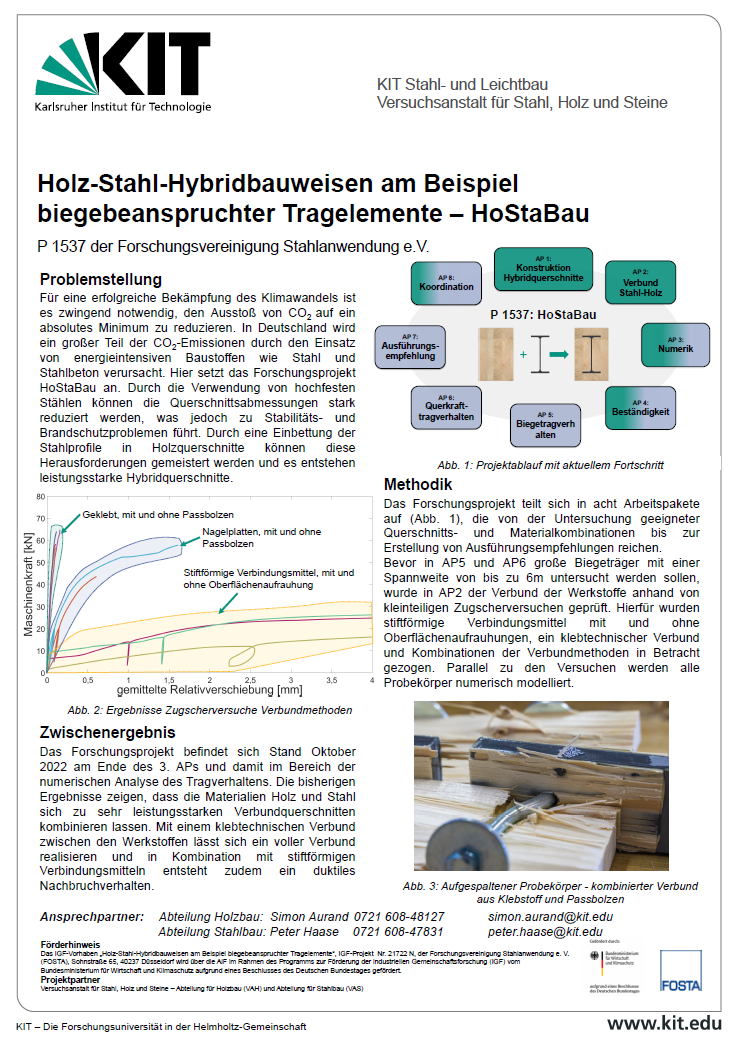

HoStaBau - Timber-steel hybrid construction

New development of a hybrid construction method through the advantageous combination of the materials steel and timber for linear load-carrying elements subject to bending load. The hybrid construction method is characterized by the shear-resistant embedding of a high-strength steel profile in a compact timber cross-section. This allows the specific advantages of the two building materials to be optimally utilized and the weaknesses of the building materials to be compensated for by the composite partner.

Contact: Simon Aurand and Peter Haase

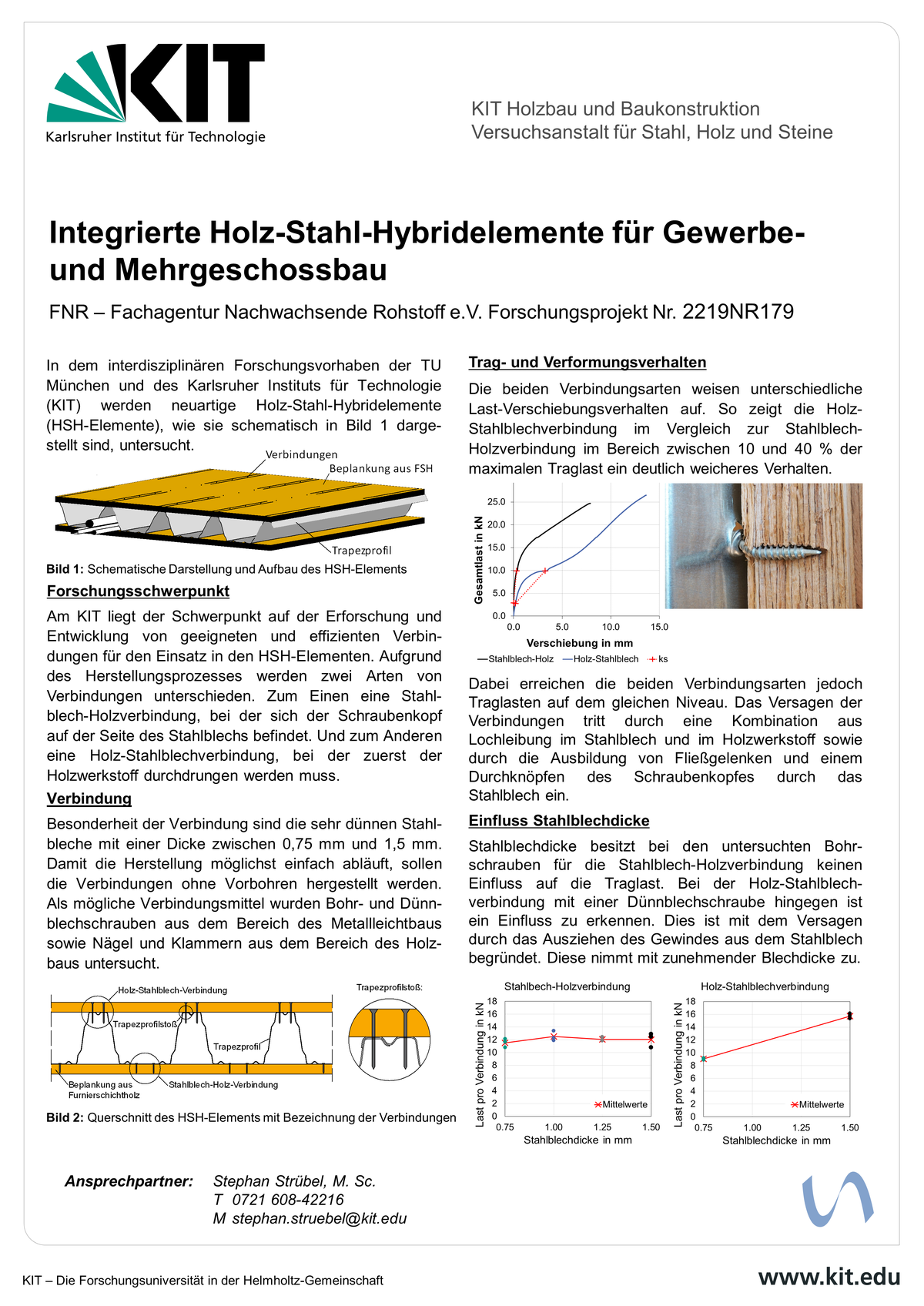

HS-Hybrid - Integrated wood-steel hybrid elements

Development of integrated timber-steel hybrid elements for commercial and multi-storey buildings with spans of up to 10 m and development of a suitable design concept.

Contact: Stephan Strübel

hardwood_joint

Development of economical, reliable and innovative joining technologies for hardwood components and corresponding design rules.

Contact: Elisabet Kuck

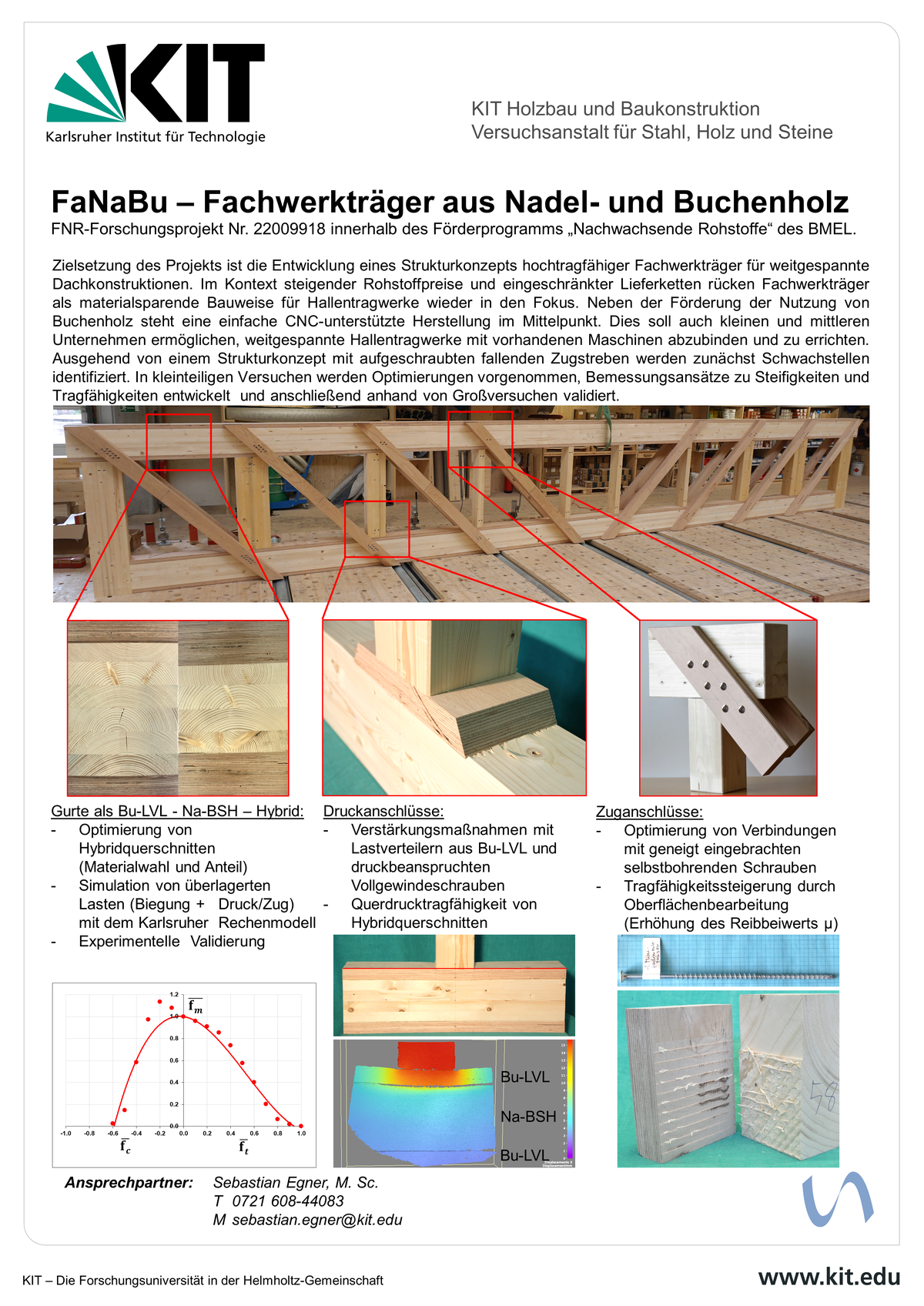

FaNaBu - Trusses made of softwood and beech wood

Development of a truss girder concept for spans of up to 100 m using laminated beech veneer lumber, hybrid beams made of softwood and beech wood, and wood screws as fasteners.

Contact: Sebastian Egner

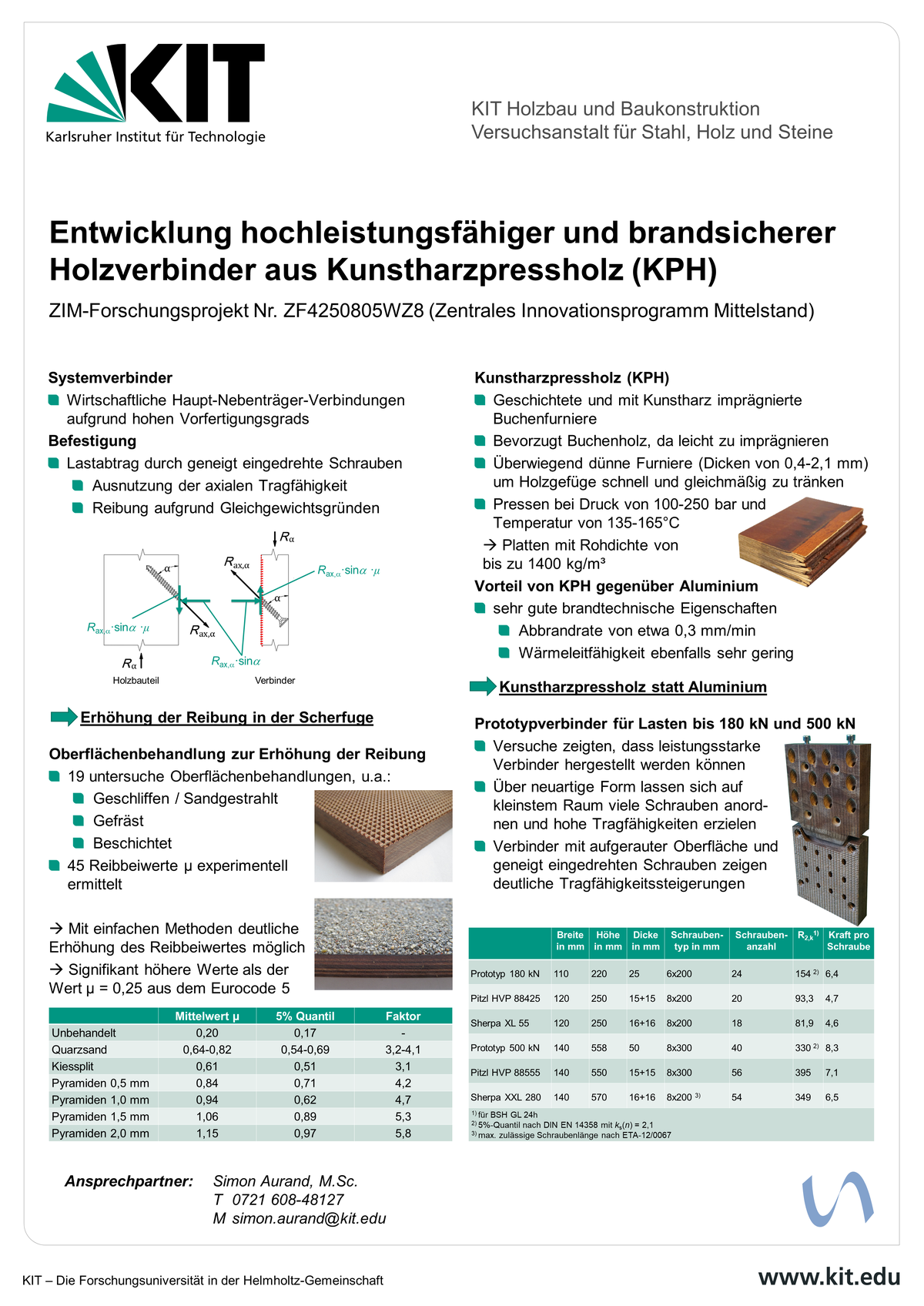

Connectors made of densified veneer wood with increased friction in the shear plane

For the first time, new connectors made of densified veneer wood (DVW) were realized. Initially, the surface of the DVW was treated to increase the friction between the connector and the timber component in the shear joints and thus significantly increase the load-bearing capacity of the connection. Friction tests were carried out to determine the friction coefficients of the surfaces. In subsequent compression-shear tests, the behavior of the surfaces in connections with inclined fully threaded screws was investigated.

Contact: Simon Aurand

Final report: Karlsruhe Reports on Timber Engineering, Volume 38

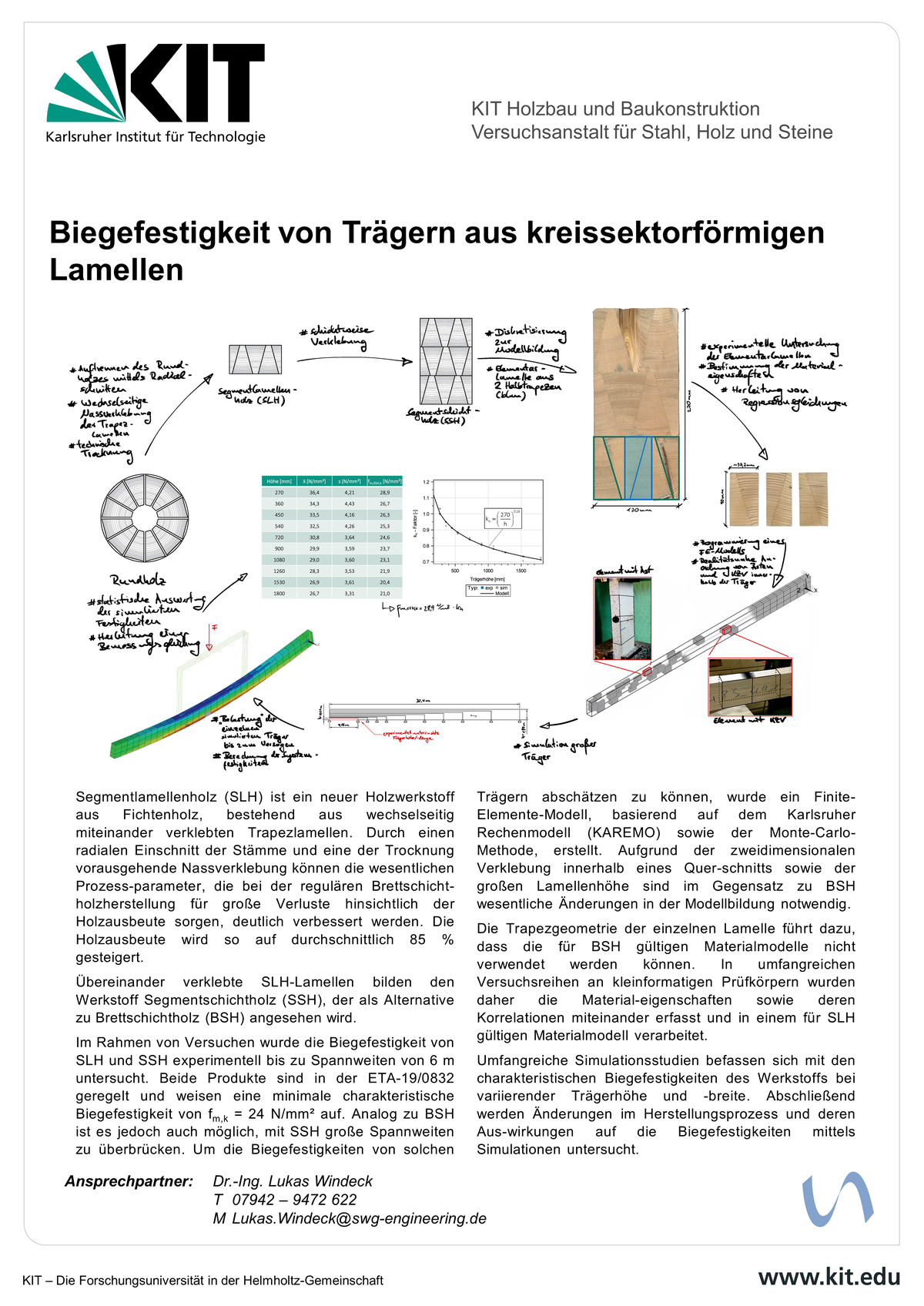

Bending strength of beams made from laminated segment timber

Laminated Segment Timber (LST) consists of mutually glued trapezoidal lamellas made of Spruce. Due to the optimization of process parameters the wood yield can be increased to an average of 85%. LST and layered LST are regulated in ETA-19/0832. Simulation studies deal with the characteristic bending strength at variing member depth and height as well as modifications in the production process.

Contact: Lukas Windeck

Final report: Karlsruhe Reports on Timber Engineering, Volume 37