WOOMI - Wood meets Minerals

Timber structures offer great potential in new buildings as well as in the extension and reinforcement of existing buildings. Timber components often have to be connected to mineral materials such as concrete. To date, however, there has been a lack of standardised concepts that holistically record the load-bearing behaviour of both building materials in the connection - the potential of such hybrid solutions is therefore not fully exploited. The aim of the project is to systematically analyse these connections and to develop suitable design methods on this basis. The interaction of the materials is to be understood in depth and realistic mechanical models developed. This will create the basis for efficient, economical and practical solutions.

Contact: Jonas Frohnhöfer

The research project is funded by the European Regional Development Fund (ERDF) in Baden-Württemberg 2021-2027 through the Holz Innovativ Programme (HIP).

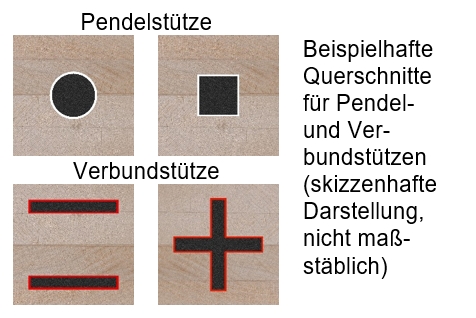

Hybrid timber-steel columns

The construction sector in Germany is responsible for considerable CO₂ emissions. This calls for innovative approaches to increase efficiency in the construction industry. As a renewable building material, wood offers great potential for CO₂ reduction, but reaches its limits in multi-storey buildings due to high static requirements. The aim of this research project is to investigate hybrid timber-steel columns that increase the load-carrying capacity, resource efficiency and range of applications by combining both materials. The research project focuses on analysing existing construction methods, designing pendulum columns and hybrid columns and evaluating the technical and ecological advantages of using them in commercial buildings.

Contact: Simon Aurand and Peter Haase

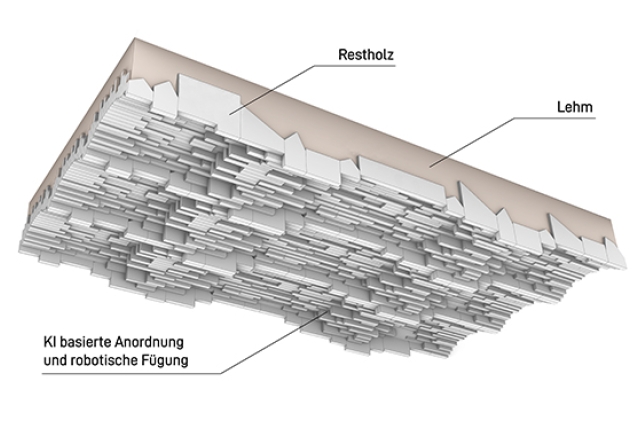

ReSidual – Timber-earth composites

The ReSidual research project aims to use digital construction technologies to make more economical use of wood as a resource in the construction industry. Waste material from the production of timber components is to be joined into load-carrying components using artificial intelligence and robotic production methods. A further reduction in the amount of wood required is to be achieved by combining it with earth. In the cooperation project between KIT Digital Design and Fabrication (DDF), KIT Timber Structures and Building Construction and the industry partner GROPYIUS, the necessary AI-based planning and robotic manufacturing processes, single-variety joining techniques and the material composite between earth and timber are to be researched. In addition to the use of residual wood in the factory investigated in the project, there are also links to the processing of residual wood and thus considerable transfer potential for realising secondary material cycles in timber structures using digital construction technology.

Contact: Simon Aurand and Daniel Fischer (DDF)

Funded by:

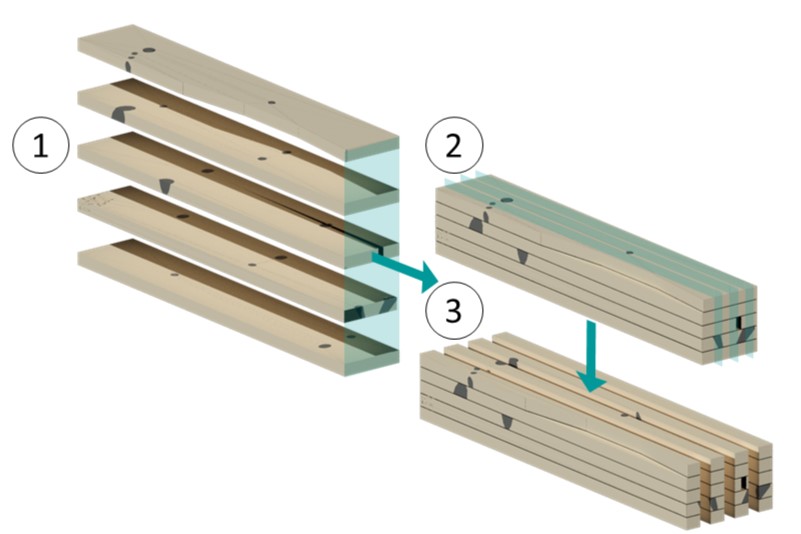

InnoTLT - Innovative Tailored Laminated Timber

Further development of cross laminated timber into a customized wood-based material adapted to the increasing demand and high material usage of solid wood products. As part of the research project, in addition to the factors influencing the load-carrying capacity, aspects of building physics, bonding and production technology of wall and ceiling elements with a wide range of variations within the material structures are also being investigated. Circularity of raw materials, resource efficiency and multi-functionality are also the focus of the European research project.

Project website: https://www.innotlt.com

Contact: Kay Ackermann

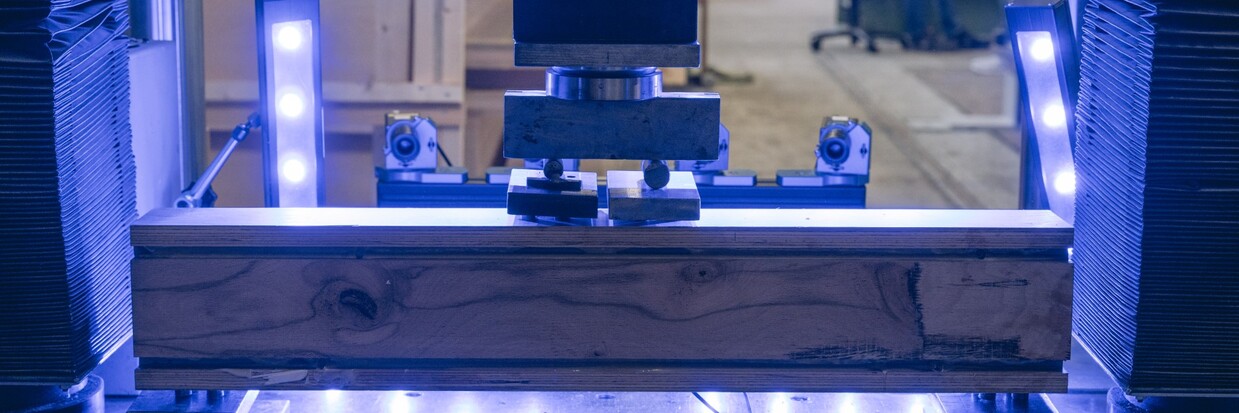

Rod laminations

The aim of the project is to develop special lamellas with cross-sections consisting of several strips glued together. The starting materials are boards and glulam from dismantled structures that are difficult to recycle. For production, glulam is cut at right angles to the glued joints as an intermediate product. Tests on individual slats, methodically adapted to the stress in the composite, form the basis for empirically representing the scattering material properties of the slats for Monte Carlo simulations. The load-bearing behavior of the special slats is thus investigated in a simulation according to the principles of the Karlsruhe calculation model. Results are validated with tests on specifically constructed special slats. Their effect in combination with conventional lamellae is also simulated and checked by means of bending tests on a component scale. Based on the research results, technical recommendations for the use of special lamellas in glulam and cross laminated timber will be developed. The aim is to achieve innovative added value with boards that are difficult to recycle and to improve resource efficiency: Deconstructed glulam cut into special lamellas corresponds to the idea of flat cascade utilization. Additional lamination and homogenization effects in the composite can be expected to improve the material value of problematic boards.

Contact: Alexander Weese

This project is funded by the Federal Institute for Research on Building, Urban Affairs and Spatial Development on behalf of the Federal Ministry for Housing, Urban Development and Building with funds from the Zukunft Bau research funding program (AZ 10.08.7-23.01).

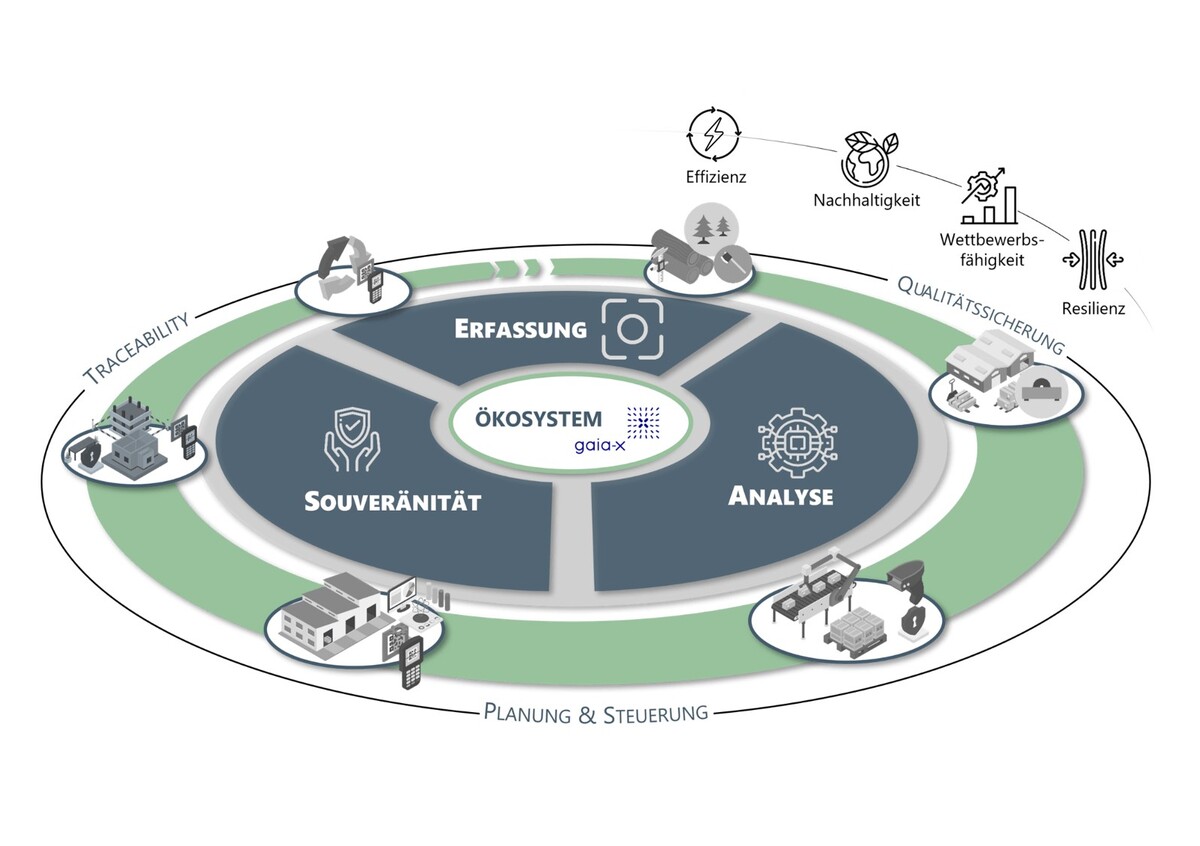

champi4.0ns

As part of the project, the use of production-relevant data is being promoted. Examples from the timber industry will be used to show how the intelligent and sovereign use of data can succeed in a federative ecosystem. In addition, methods and services for addressing key challenges will be developed and made available. The intention is to realize and document demonstrators, further develop and apply big data technologies, co-design and apply guidelines and standards, build skills and capacities and promote exchange between stakeholders. champi4.0ns demonstrates the added value of using data in the fields of traceability, planning and control and quality assurance in the timber industry and beyond.

Project website: https://www.champi40ns.eu/

Contact:

Funded by:

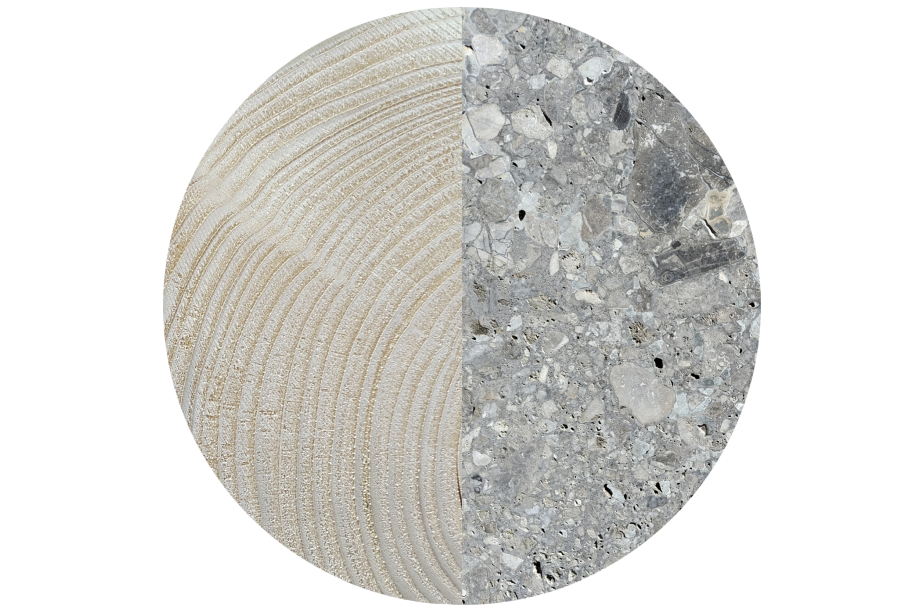

Kiri wood

In view of the increased threat to spruce stocks due to climate change, wood-based materials made from alternative wood species will be needed in the construction industry in the medium term. The aim of this project is therefore to develop load-bearing construction products made from the wood of the fast-growing and drought-resistant bluebell tree (also known as Kiri or Paulownia spp.) and to facilitate their development and introduction. However, since kiri wood is significantly lighter than spruce wood and has different mechanical and anatomical properties, it is first necessary to create a basic database in order to be able to successfully carry out strength grading of boards made from kiri wood. In a second step, these boards are to be used homogeneously and combined with spruce wood in timber products such as glulam or cross laminated timber and investigated.

Contact: Alexander Weese

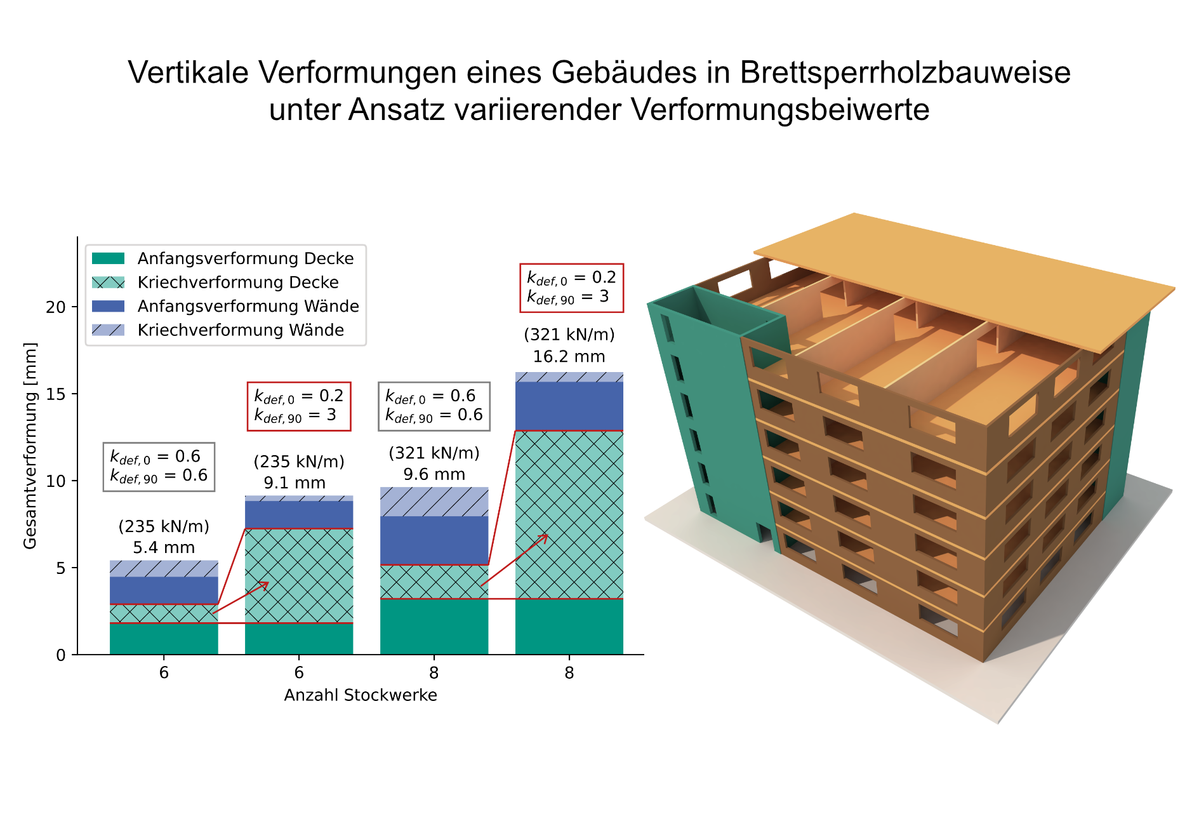

Minimized deformations of compression perpendicular to grain in multi-storey timber buildings

The construction of multi-storey timber buildings is state of the art today. The so-called platform construction method is often used, in which the ceilings are placed on single-storey walls. As the number of storeys increases, this results in high compression stresses perpendicular to the grain in the ceilings, which lead to vertical deformations. The short-term deformations are comparatively easy to calculate. Long-term deformations, on the other hand, are difficult to estimate as there are no differentiated deformation coefficients kdef for compression stresses perpendicular to the grain . These deformations are particularly relevant in hybrid timber buildings, for example, where parts of the supporting structure, such as the access cores, are constructed in the form of reinforced concrete cores.

The aim of the project is to develop construction details with minimized deformations of compression stresses perpendicular to the grain in multi-storey timber construction and to determine creep coefficients for compression loads perpendicular to the grain.

Contact: Christian Bertram

Funded by:

DiaLagHolz - Diagonal laminated timber

In private house construction, cross laminated timber panels are used for ceilings and walls in addition to timber panel construction. Cross laminated timber has a very high weight, which is primarily due to the high amount of wood used in the cross laminated timber elements. For this reason, the development of a diagonal laminated timber lightweight wall is planned as part of the development project. This makes it possible to achieve a considerable weight saving of up to 40% by profiling the internal board layers to meet specific requirements. By arranging some layers diagonally, mechanical properties can be achieved that are equal to or higher than those of cross-laminated timber panels. The additional air inclusion through the profiling also ensures a higher thermal insulation value with corresponding diffusion openness.

Contact: Stephan Strübel and Kay Ackermann

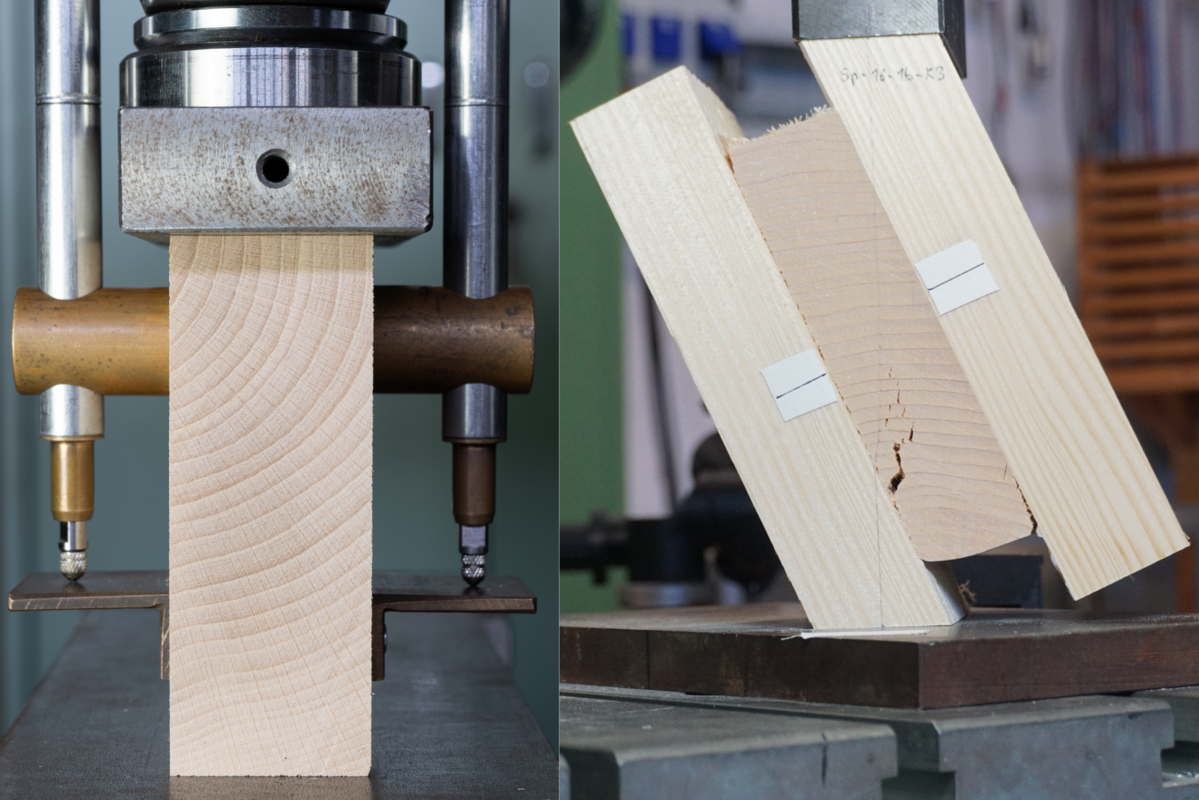

Hardwood joints

In hardwood connections with dowel-type fasteners subjected to lateral loading, the high bulk density leads to high load-carrying capacities and has an influence on the load-carrying behavior. Material properties and system parameters such embedment strength, pull-out and head pull-through strength influence the joint behavior and also the failure modes. Failure of the fastener cross-sections can be observed more frequently due to the higher stress in hardwoods. When subjected to lateral loading, the fasteners exhibit a multiaxial stress state, as bending moments, shear forces and normal forces can act simultaneously. Depending on the type and geometry of the fastener, these vary and can lead to a shear or tensile failure of the fastener as part of an interaction of internal forces. The investigation of the new type of failure aims at a comprehensive understanding and full utilization of the connections.

Contact: Elisabet Kuck

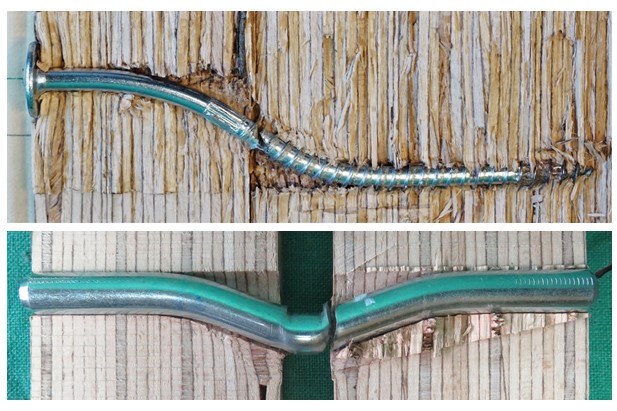

Position imperfections of self-drilling screws in wood and wood-based materials

Position imperfections of self-drilling wood screws are characterized by deviations between the planned and actual screw channel. They occur unintentionally during self-drilling screw insertion and increase with increasing screw-in length. With long, slender screws, positional imperfections are insufficiently compensated for by minimum distances. Within crossed arrangements, this can lead to contact or collisions between screws. Possible consequences are thread damage, plastic deformation or even twisting or breaking of the screws. This affects the mechanical effectiveness of a screw connection and reduces its load-carrying capacity and durability. The IGF research project involves investigating the causes of positional imperfections and the damage mechanisms. The aim is to develop models to describe positional imperfections and to formulate practicable solutions to avoid contact and collision-related problems in screwed connections.

Contact: Eva Baldauf

Lövträ

Lövträ is a cooperative research project of Linné University in Sweden with the participation of KIT. The subject is the investigation of the material behavior of hardwoods. Due to their increased mechanical properties compared to softwood, this type of wood allows a reduction in the required cross-sectional dimensions and is suitable for reinforcing softwood products. In addition to being used for reinforcement for compression perpendicular to grain stresses, transverse layers of hardwood in cross laminated timber are conceivable for increasing the rolling shear strength, for example. However, little is known about the long-term behavior of hardwoods and the influence of different climates. In order to close this gap, tests are being carried out under various climatic conditions. The focus is on the compression perpendicular to the grain, rolling shear and embedment strength. The test program includes both short-term and long-term tests. Southern Swedish beech and birch timber as well as spruce are tested as a reference. The results are intended to support the usability of hardwoods in the construction industry.

Contact: Elisabet Kuck and Christian Bertram

Funded by: